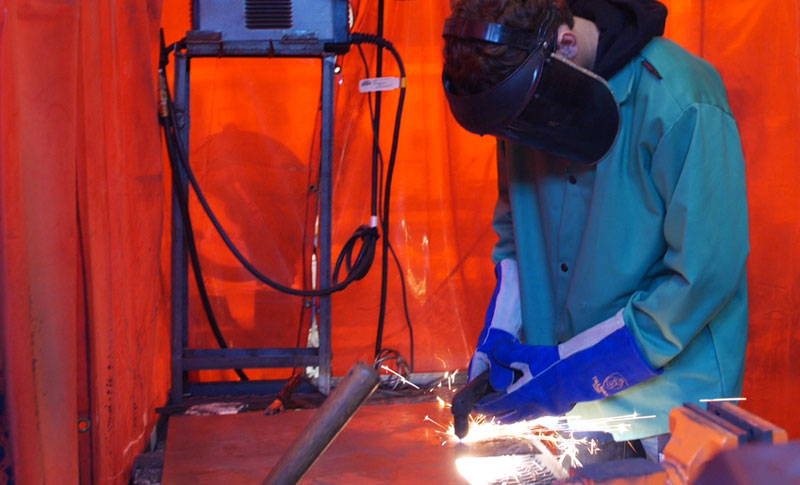

The Systems Tech Program is offered to all juniors and seniors and prepares students who may want to enter or further their education in welding and metal fabrication. For students who want to learn more about this field sooner, they can take one of the Metals and/or Welding elective courses as a freshman and/or sophomore. Skills in this career field are in high demand and students are also prepared to enter a PreApprenticeship program their senior year.

Junior Year Overview

Junior students will learn the production processes applied across manufacturing operations and be able to demonstrate a broad array of technical skills with an emphasis given to quality practices, measurement, maintenance and safety. In addition, they will gain fundamental welding principles involving shielded metal arc, oxyacetylene, gas tungsten and gas metal arc welding in the flat, horizontal and vertical positions while also learning joint designs and layout and welding codes and standards.

Senior Year Overview

Senior students will develop knowledge and skills necessary for installing, maintaining and safely troubleshooting modern industrial machinery. Seniors will learn about pneumatic, hydraulic, mechanical and electrical systems as well as how to troubleshoot electrical controls, sensors and actuators for automated machinery and manufacturing processes. In addition, students will learn the fundamental principles and practices of cutting, drilling and grinding using modern machine tools, hand tools and precision measuring instruments.

Systems Tech students also participate in the Lancaster SkillsUSA chapter, where they gain many valuable leadership skills and can compete at the regional, state and national level. Students can begin working in the industry their senior year to get a headstart on their careers!

Instructor: Eric Morris || e_morris@lcsschools.net

Possible Careers

- Mechanical Engineer

- Robotics Specialist

- Fabricator

- Electrical Engineer

- Machining Technician

- Welder

Certifications

Junior Year

Ohio State Apprenticeship Council Recognized Pre-Apprenticeship Program Certificate of Completion (Must pass Welding course

12 Credential Points

Manufacturing Skill Standards Council (MSSC) – Certified Production Technician (Safety)

3 Credential Points

Manufacturing Skill Standards Council (MSSC) – Certified Production Technician (Manufacturing Processes & Production)

3 Credential Points

OSHA 10

1 Credential Point

Senior Year

Manufacturing Skill Standards Council (MSSC) – Certified Production Technician (Maintenance Awareness)

3 Credential Points

Manufacturing Skill Standards Council (MSSC) – Certified Production Technician (Quality Practices & Measurement)

3 Credential Points

Core Skills

- Design fabrication

- Installation of equipment

- Electrical/electronics

- Machining

- Automated systems

- Teaching methods and strategies

- Robotics

- Welding

- Fluid power applications